Tel : 86-531-88683323

E-mail:sdpropellent@pl-heatexchanger.com

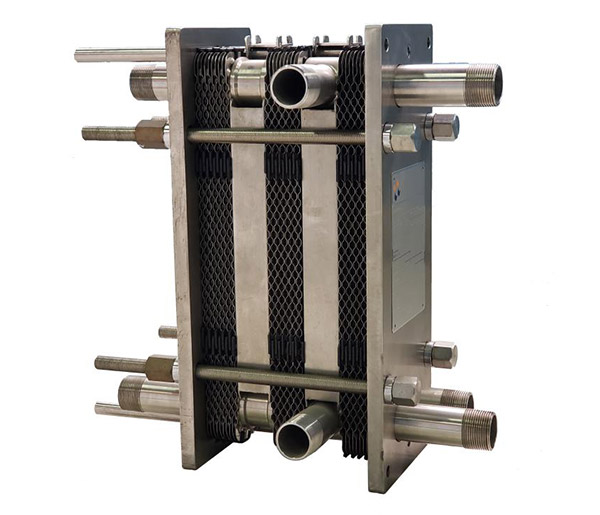

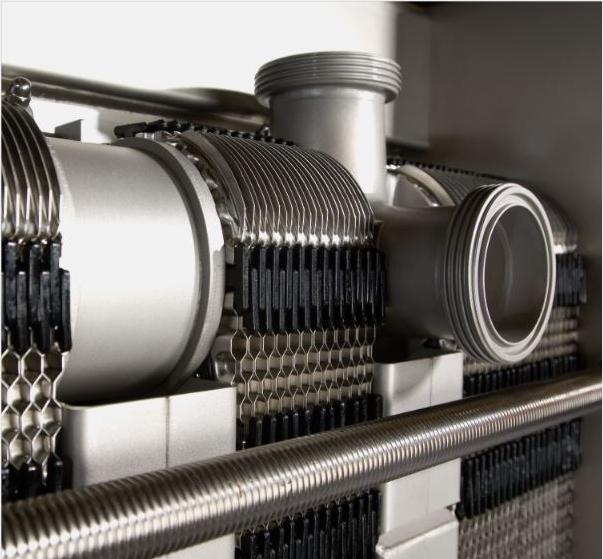

Propellent sanitary plate heat exchangers are designed for food and beverage industry. With different types of plates and pressing depth, which are available for gentle, uniform heat treatment of sensitive dairy, food and beverage products. The applications such as, heating and cooling processes, pasteurization of milk, beer, juice and viscous products.

Our wide gap free flow plate has a wider plate pattern, which without contact points, makes it ideal for products containing pulp or fibres.

Food grade materials and structure

Signal-stage type and multi-stage type

|

Propellent Plate Heat Exchanger |

|

|

Flow rate |

300 L/H~50000 L/H |

|

Flow Channel Between Plates |

3.5mm ~12.0mm (Optional depends on working condition) |

|

Plate Thickness |

0.4mm ~ 1.0mm |

|

Heat Transfer Plate Material |

Stainless steel - 304/304L, 316/316L, |

|

Gasket Material |

NBR, EPDM, FKM |

|

Pressure Plate Material |

Stainless steel |

|

Temperature Range |

-50℃ ~ +180℃ Varies with the media and gasket selection. |

|

Maximum Pressure |

Maximum standard pressure 6 bar/ 10 bar / 16 bar |

|

Port Connection |

DN32, DN50, DN80, DN125, DN150 |

|

Model |

Connection pipe diameter |

Dimensions(mm) |

Area(m2) |

|

PL32 |

DN32 |

550*129 |

0.05 |

|

PL50 |

DN50 |

780*212 |

0.15 |

|

PL80 |

DN80 |

999*337 |

0.30 |

|

PL80P |

DN80 |

999*338 |

0.30 |

|

PL125 |

DN125 |

1400*425 |

0.46 |

|

PL200 |

DN200 |

1766*614 |

0.84 |

|

PL50T |

DN50 |

492*246 |

0.07 |

|

PL50M |

DN50 |

864*246 |

0.18 |

|

PL50X |

DN50 |

1236*246 |

0.26 |

|

PL100T |

DN100 |

897*445 |

0.30 |

|

PL100M |

DN100 |

1303*445 |

0.52 |

|

PL100X |

DN100 |

1709*445 |

0.76 |

|

PL150L |

DN150 |

1800*541 |

0.96 |

|

PL150S |

DN150 |

1320*541 |

0.62 |

|

PL250S |

DN250 |

1736*745 |

1.10 |

|

PL250M |

DN250 |

2033*745 |

1.13 |

|

PL250L |

DN250 |

2330*745 |

1.70 |

|

PL350S |

DN350 |

2140*995 |

1.74 |

|

PL350M |

DN350 |

2477*995 |

1.70 |

We have specialized in the development and manufacturing of heat exchangers. A variety of variant patterns are designed to create different levels of turbulence and pressure drop, to meet with different heat transfer requirements.

Applications:

Pasteurization

Milk

Cream

Beer/ brewing

Juice

Yoghurt

Honey

Requset a quote

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español