There are pathogenic bacteria, spoilage bacteria and other pathogenic microorganisms in food due to contamination. In order to kill pathogenic microorganisms in food materials, and to ensure that the food has a certain shelf life and retain the nutrients of the food, a complete set of equipment for sterilizing and cooling the materials is required to eliminate pathogenic microorganisms and extend the shelf life of the materials.

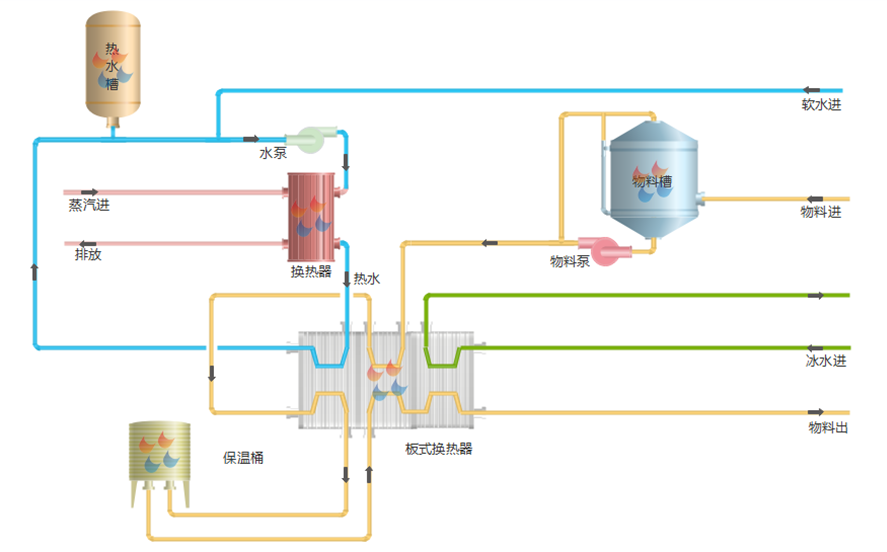

The PP state food sterilization solution adopts the company’s advanced plate sterilizer and sterilization system. Through the non-contact heat exchange between the material and superheated steam (or superheated water), the fluid material can reach the required sterilization temperature in a short time. To achieve the purpose of extending the shelf life of materials and retaining nutrients.

Our company can design the system according to the user's process requirements for material heating, sterilization, heat preservation and cooling, and can be supplemented by an automatic control system to make the entire sterilization device run reliably.

a. Short sterilization time and high sterilization effect

b. Use food-grade stainless steel materials to ensure that it meets food safety and sanitation index requirements

c. High heat recovery efficiency, energy saving and consumption reduction

d. Simple structure, convenient operation and easy cleaning

e. Automatic control system can be used, stable and reliable operation

It is suitable for pasteurization, high temperature short-time sterilization, ultra-high temperature sterilization of similar liquid materials such as dairy products, juices, beer, beverages, and can also be used for heating, sterilizing and cooling fresh milk or dairy products.

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español