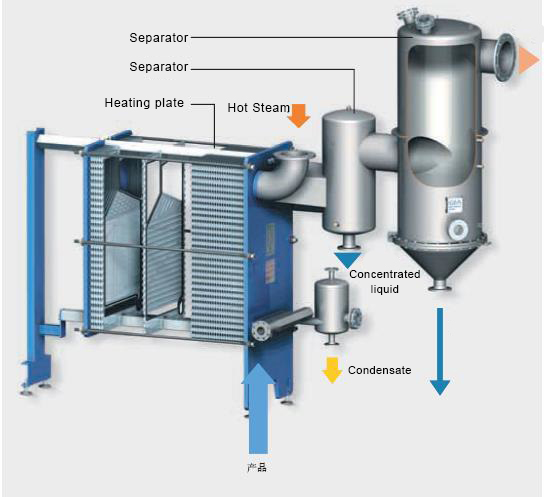

Propellent Plate evaporators and condensers use climbing-falling film evaporation, the materials pass between the plates and are heated by steam to evaporate. Enrichment of the material and the second steam will continue to evaporate into the next level of evaporator, It has high thermal efficiency, compact structure, convenient disassembly cleaning.

The working principle of evaporation is to remove a large amount of water or vaporizable solution from the material through isolation heating method to achieve the purpose of concentrating the material.

Unique asymmetric large porthole of the Propellent evaporator ensures the most efficient heat transfer. Strong evaporation effect and large heat transfer coefficient depend on Propellent’s special design plate. The premium patterns of the plate make the fluid flow arise intensive turbulence. Operating very convenient with the compact structure and small size, and easy to observation.

The solution is used in the evaporation and concentration, evaporation and condensation of sucrose, glucose, maltose, sorbitol, black liquor, barium chloride, calcium chloride, metallurgy, food, paper, chemical, desalination and other product industries.

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español