Tel : 86-531-88683323

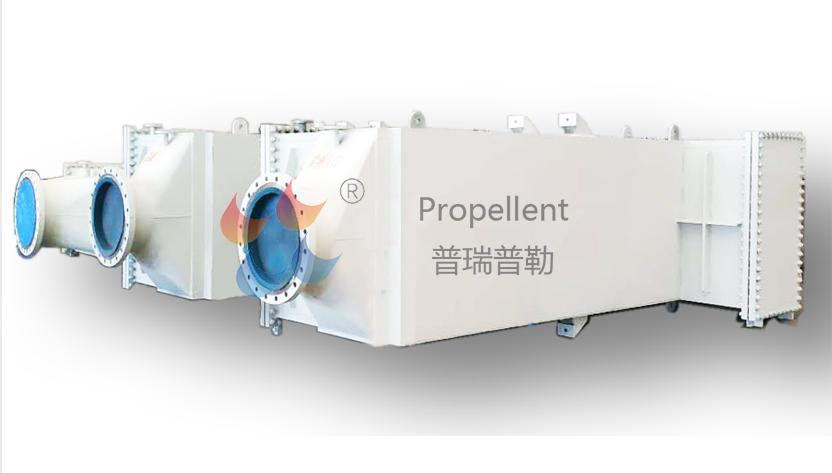

E-mail:sdpropellent@pl-heatexchanger.comWelded plate heat exchanger

Prepollent all welded plate heat exchanger is well suited for applications involving high temperature and high pressure with relatively clean media. The fully welded design makes this type of heat exchanger is well used above all in the oil and gas industry, the chemical industry as well as in the petrochemical sector. The media can also be very corrosive.

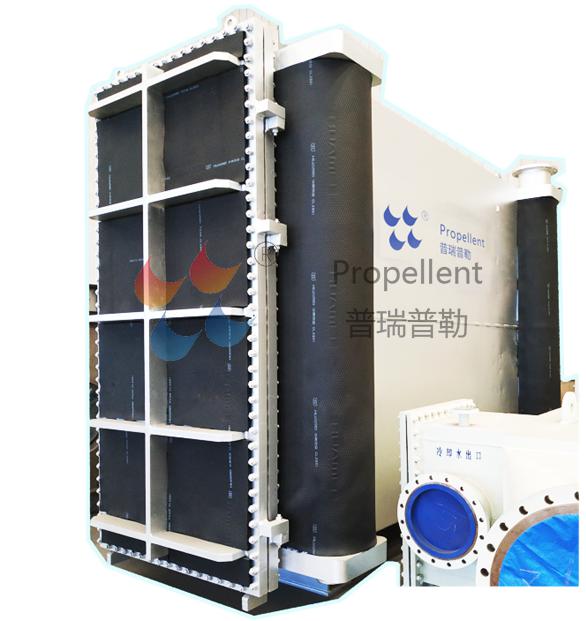

The fully welded plate heat exchanger is sealed with advanced fully welded technology. The gasketless design solves the problem of low temperature and pressure resistance of the detachable plate heat exchanger. Mean while, the width of the runner can be adjusted according to the application conditions.

Application for

liquid-liquid / gas-liquid / gas-gas heat transfer, customized according to working conditions.

Technical features:

-Full welding process, no gasket seal

-High temperature and high pressure resistance

-High pressure resistance can reach 4.0Mpa, high temperature resistance can reach 250~300℃. -High heat transfer efficiency

-Wide range of applications

The plate bundle and compression plate are all welded structures, which can be used in situations where the temperature is ≤300℃, the pressure is ≤4.0Mpa, or the working medium corrodes the gasket, and the environment requires high safety conditions.

Suitable for oil refining, petrochemical, electric power, metallurgy, and steel plants. Mainly waste heat recovery from sewage, waste heat recovery from flue gas, air-to-air heat exchange, slurry cooling, etc.

Requset a quote

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español