Petroleum and chemical industries are the main application areas of heat exchangers. Almost all processes in petroleum and chemical production have heating, cooling or condensation processes, and heat exchangers are required. The performance of the heat exchanger plays an important role in the quality of petrochemical products, the heat utilization rate, and the economy and reliability of the system. At present, the heat exchanger is developing in the direction of large-scale, high efficiency, high alloying, low temperature difference, and low pressure loss.

Application of plate heat exchanger in petrochemical industry

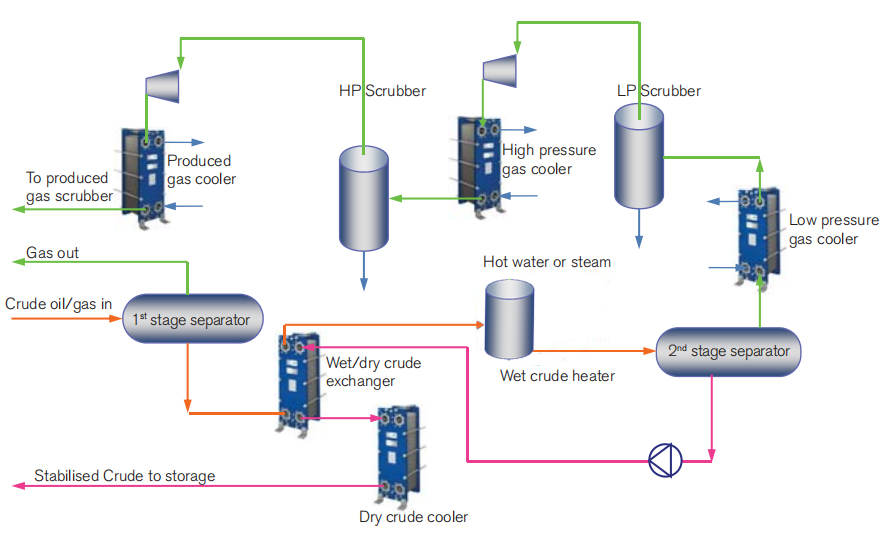

In the petrochemical industry, with the continuous improvement of production technology, plate heat exchangers are gradually used in the liquefaction and separation of natural gas, and in the synthetic atmosphere industry. In the chemical industry, plate heat exchangers are used in heavy oil catalytic cracking units.Application. The application of plate heat exchangers in the petroleum industry is mainly in the heating and cooling of various oil products, the condensation and cooling of tower overhead gas, the factory cooling water system, the treatment of factory acid water, and the use of marine drilling platforms for seawater cooling and circulating fresh water or Ethylene glycol crude oil cooling, desalination unit, fresh water distillation, heat recovery and cooling air during dehydration of triethylene glycol. In petrochemical plants, the advantage of using plate heat exchangers is that due to the small temperature difference, it can not only make full use of cold capacity, reduce irreversible losses due to temperature differences, but also change the level of refrigeration, thereby reducing the power required for refrigeration.

Plate heat exchanger is a kind of traditional heat exchange equipment, which has the advantages of convenient manufacture, wide selection of materials, strong adaptability, large processing capacity, convenient cleaning, reliable operation and ability to withstand high temperature and high pressure.

Cooling process of crude oil.

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español