The centrifuged liquid of distillers grains refers to the clear liquid after the separation of the distiller's grains liquid discharged from the bottom of the crude distillation tower, and the temperature is 80~82℃.

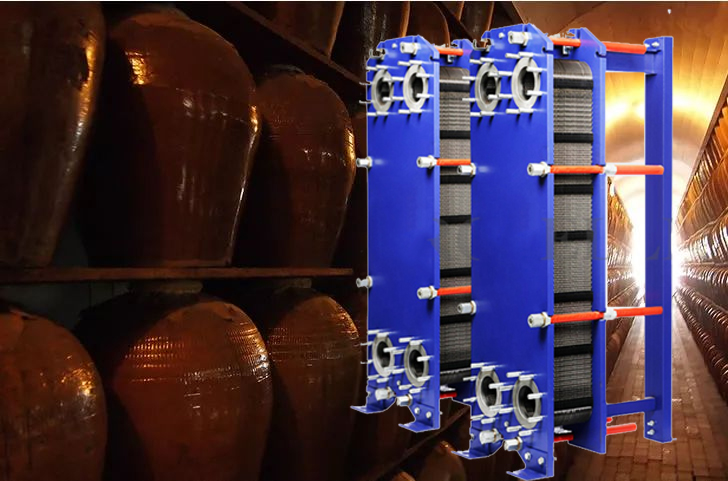

The clarified liquid directly flows into the saccharification tank and returns to the system after being mixed in the stirring tank, but due to the high temperature, the loss of activating enzyme activity is large. Therefore, before it enters the system, it must be cooled before it can be used. In order to obtain the alcohol clear liquid with high active enzyme activity, it must be cooled by a plate heat exchanger.

The cooling of 95% alcohol products adopts plate heat exchanger, which has a remarkable effect. The temperature difference between the inlet and outlet of the cooling water can be about 40~50℃, and the outlet temperature of the cooling water can be 65℃ and higher. The cooling water consumption of the plate heat exchanger is only 1/3 of the cooling water consumption of the tubular cooling heat exchanger. In addition, the plate heat exchangers occupies a small area. For example, the area of plate heat exchangers in an alcohol factory with an annual output of 20,000 tons is only 3 square meters.

Saccharified mash refers to the starchy raw material, and the mixture formed after saccharification is the raw material pretreatment process before entering the fermentation tank for fermentation. After the starchy raw material is saccharified, it can be fermented with Saccharomyces cerevisiae in a sealed fermentation tank to produce alcohol. When designing the heat exchanger for the cooling process of Saccharified mash (the temperature of mash is generally 20℃-40℃), the material properites of the mash should be considered. Based on the properites of high concentration, high viscosity and high solids content, the large size plate heat exchanger is applicalbe, which with features of low pressure drop, wide flow channel and blockage avoided. Through experiments in an alcohol factory using corn as raw materials, it is considered feasible.

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español