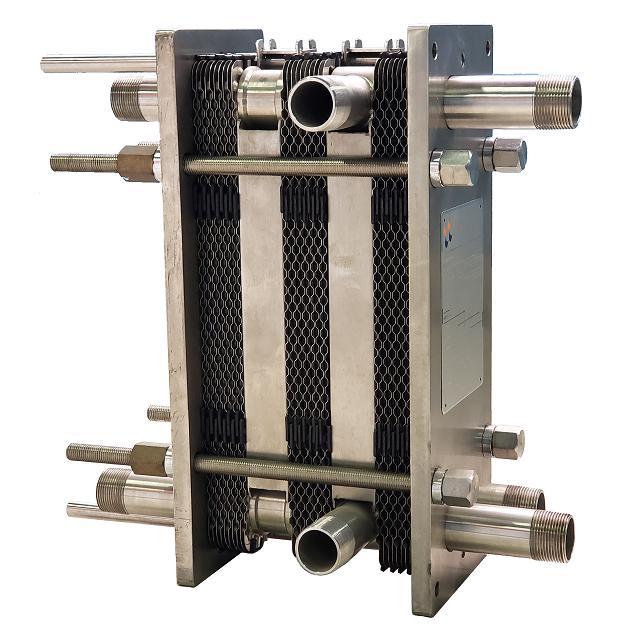

In the beer production process, the cold consumption of hot wort cooling water is quite large, accounting for about 50% of the total cold consumption of the entire beer production. The wort cooling equipment uses thin-plate heat exchangers, which are made of stainless steel. The cooling equipment is composed of many thin plates with grooves on both sides, two pieces in a group, as a basic unit. When the wort is cooled, the hot wort and the cooling medium are pumped to flow in turbulent flow along the grooves on both sides of the groove plate to exchange heat. There are mainly two ways, namely two-stage cooling and one-stage cooling. In the past, the two-stage cooling method was the most common application, but now the one-stage cooling method is increasingly used.

The traditional cooling process is Multi-stage cooling: an intermediate plate is installed between the two stages. The first stage of cooling is to use tap water as the cooling medium to cool the wort from about 95°C to 40-50°C, and the cooling water is heated from nearly 20°C to about 55°C; the second stage of cooling is to use a deep cooling refrigerant (ethanol Or ethylene glycol solution) as the cooling medium, the wort is further cooled to about 7°C in the fermentation tank, and the refrigerant is heated from -4 to 3°C to about 0°C, and then returned to the refrigeration station for re-cooling before recycling. The water after the previous heat exchange can be used as feed water.

One-stage cooling method: This method uses a cooling medium to cool the hot wort (about 95°C) to the temperature of the inoculation yeast (about 7°C) at one time. The cooling medium is brewing water, which is first cooled to 2~4℃ (commonly known as ice water) by ammonia direct cooling, and then heated to 75~80℃ after heat exchange with hot wort. This water can be directly used as lees washing water use.

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español