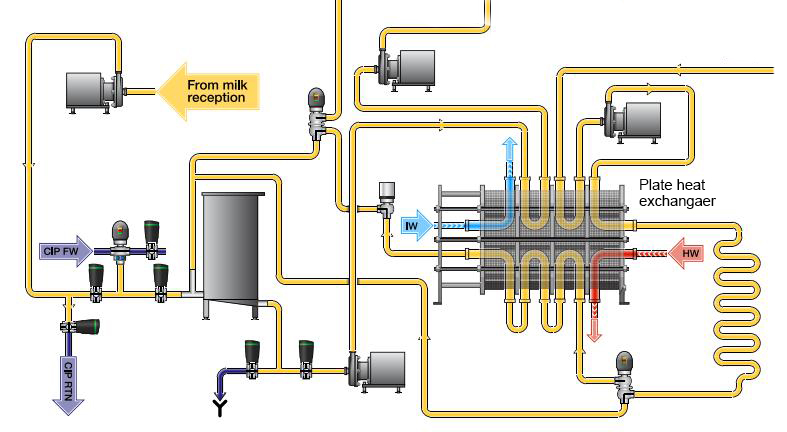

Milk heating and cooling process

Milk pasteurization

Sterilization of milk

During the production process, the fresh milk needs to be quickly cooled to inhibit the reproduction of microorganisms and extend the duration of the antibacterial properties of the milk. The cooled milk needs to be sent to the factory for processing in time. After filtration, purification, cooling, homogenization, sterilization and packaging, it becomes the disinfected milk that people drink daily.

Sterilization is an important process in the production of sterilized milk. Usually pasteurization is adopted (this method is divided into low temperature and high temperature disinfection methods. The low temperature disinfection method is to put the milk in a special pasteurizer, and heat the milk to 62℃~65℃ for 30 minutes; The high temperature sterilization method is to heat to 73.8℃~76.6℃ for 1~10 minutes, or 82.2℃ for no more than 5 minutes. Then quickly cool to 10℃. The purpose of cooling is to prevent the remaining spores from multiplying and keep the milk quality.

Multi-stage sanitary plate heat exchanger

TEL: 86-531-88683323

Email: sdpropellent@pl-heatexchanger.com

ADD: 5F, Xinsheng Building #2 Xinluo Street 1299, Hi-Tech District, Jinan, Shandong, China

Español

Español